Bar Cutting Machines in Bawana: Enhancing Efficiency in Modern Construction

Introduction

In the fast-paced construction industry of Bawana, efficiency and accuracy are key to completing projects on time and within budget. Among the essential equipment on construction sites, the Bar Cutting Machine stands out as a crucial tool for preparing reinforcement steel bars (rebars).

These machines automate the cutting process, ensuring precise measurements, improving productivity, and enhancing safety for workers. Whether for high-rise buildings, bridges, or residential complexes in Bawana, Bar Cutting Machines play a vital role in modern construction. For complete product details, you can check here: Bar Cutting Machine.

What Is a Bar Cutting Machine?

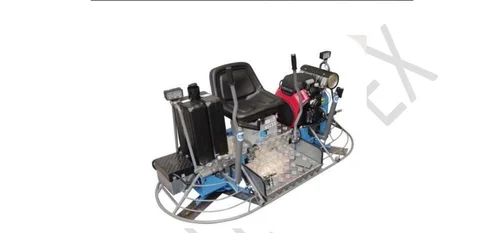

A Bar Cutting Machine is specialized equipment designed to cut steel reinforcement bars into specific lengths for concrete structures. Traditional methods, like manual sawing or gas torch cutting, are slow, inconsistent, and hazardous.

Modern Bar Cutting Machines in Bawana use mechanical or hydraulic systems to deliver fast, clean, and precise cuts. These machines ensure each bar fits perfectly into the structural framework, minimizing waste and errors.

Why Bar Cutting Machines Are Essential in Bawana

1. Speed and Efficiency

Manual cutting is time-consuming. Using a Bar Cutting Machine allows workers in Bawana to cut hundreds of bars quickly, keeping projects on schedule.

2. Precision and Accuracy

Structural integrity depends on rebars being cut to exact dimensions. These machines guarantee uniformity, ensuring all bars meet project specifications.

3. Safety Improvements

By reducing manual labor and eliminating dangerous cutting tools, Bar Cutting Machines enhance safety on construction sites in Bawana.

4. Cost Savings

While the initial investment is higher, machines reduce labor costs, minimize material waste, and increase overall efficiency.

5. Scalability

From small residential projects to large infrastructure works in Bawana, Bar Cutting Machines can handle various workloads efficiently.

Types of Bar Cutting Machines

Different projects in Bawana require different kinds of machines:

1. Manual and Semi-Automatic Cutters

Basic machines relying on hand operation or simple motors, suitable for small projects.

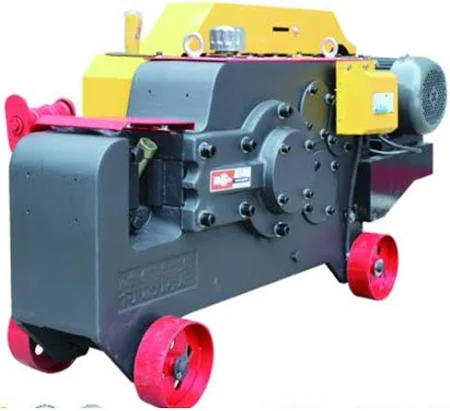

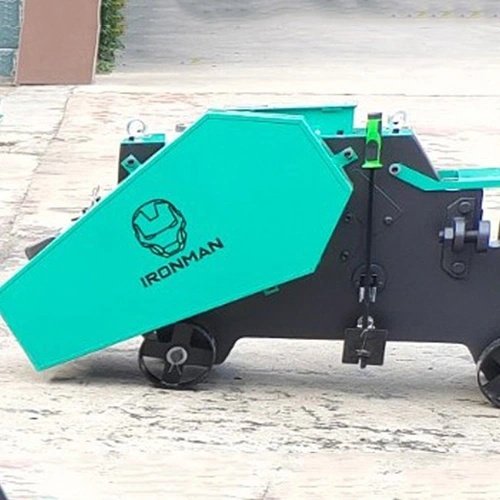

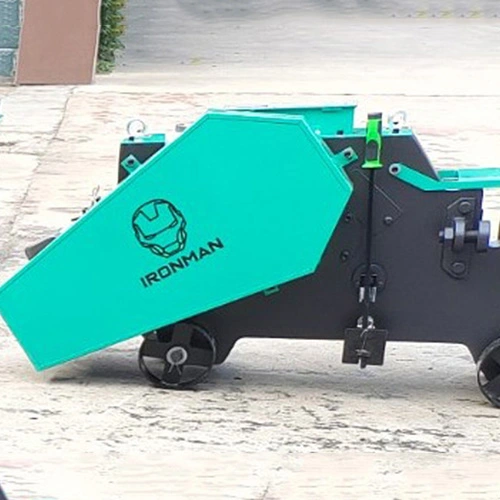

2. Hydraulic Bar Cutting Machines

Powerful machines that cut thick rebars effortlessly. Ideal for medium to large projects in Bawana.

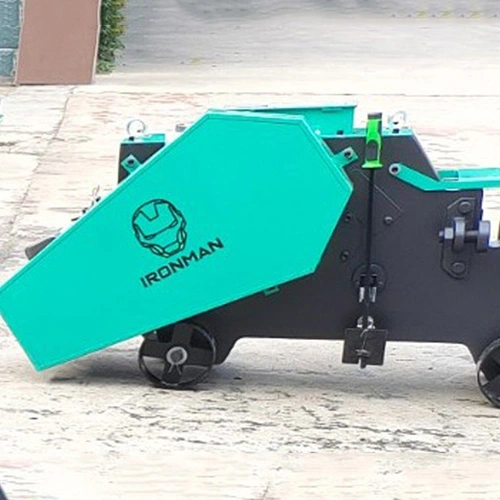

3. Electric / Motorized Rebar Cutters

Machines powered by electric motors allow high-speed cutting for multiple bars efficiently.

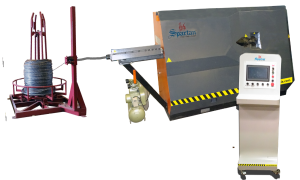

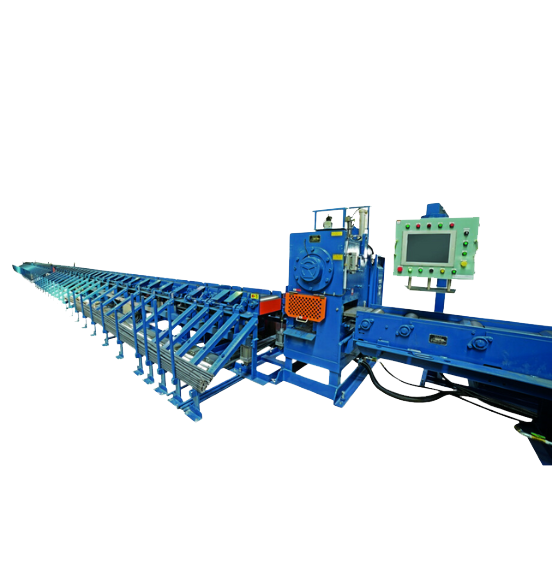

4. Automatic / CNC Bar Cutting Machines

Advanced models with programmable controls can automatically measure, cut, and eject bars—perfect for factories or large-scale construction in Bawana.

5. Rotary Disc Cutters

Machines using high-speed abrasive discs to cut bars that are difficult to shear, ensuring clean, precise cuts.

For more details about the latest models and types, read: Introducing the Latest Bar Cutting Machines for Efficient Construction.

Key Features of a Good Bar Cutting Machine

When selecting a machine for construction in Bawana, consider:

-

Cutting Capacity: Maximum bar diameter the machine can handle.

-

Motor Power: Ensures smooth and fast cutting operations.

-

Blade Strength: Hardened steel blades for durability and precision.

-

Cycle Time: Faster cycles increase productivity.

-

Automation Level: Advanced machines reduce labor requirements.

-

Safety Systems: Emergency stops, guards, and overload protection.

-

Durability: Strong frame and wear-resistant parts ensure long-term performance.

Advantages of Using Bar Cutting Machines in Bawana

-

Consistent Quality – Accurate cuts every time reduce errors.

-

Labor Reduction – Fewer workers required compared to manual cutting.

-

Higher Productivity – Multiple bars can be cut quickly to meet project demands.

-

Reduced Material Waste – Precision cutting lowers scrap rates.

-

Enhanced Safety – Minimizes risk of accidents on site.

-

Cost-Effective – Saves money in labor and material over time.

For more information on productivity and efficiency, visit: Bar Cutting Machine Enhancing Precision and Efficiency in Light Construction.

Applications of Bar Cutting Machines

Bar Cutting Machines are used across multiple projects in Bawana:

-

Residential Construction: Preparing rebars for slabs, beams, and columns.

-

Commercial Buildings: Cutting large quantities of rebars for multi-story structures.

-

Infrastructure Projects: Bridges, highways, and flyovers require precision-cut bars.

-

Industrial Structures: Factories and warehouses use machines for consistent rebar processing.

-

Precast Concrete Units: Ensures exact lengths for prefabricated elements.

Choosing the Right Bar Cutting Machine

Selecting the right machine in Bawana depends on:

-

Project Size: Large projects may require fully automatic CNC machines.

-

Bar Sizes: Machines must handle the maximum bar diameter needed.

-

Budget and ROI: Advanced machines deliver better efficiency, offsetting higher initial costs.

-

Maintenance Needs: Easy-to-maintain machines reduce downtime.

-

Safety Compliance: Must meet local construction safety standards.

Maintenance Best Practices

To ensure longevity and performance in Bawana:

-

Lubricate moving parts regularly.

-

Inspect blades and replace if worn.

-

Check electrical connections and hydraulic systems periodically.

-

Train operators in safety procedures.

-

Keep spare parts available for quick replacements.

Future Trends in Bar Cutting Machines

Expect these innovations in Bawana:

-

IoT-Enabled Machines: Remote monitoring and predictive maintenance.

-

Smart Controls: Automatic adjustments for different bar diameters.

-

Energy Efficiency: Reduced power consumption without compromising performance.

-

Integrated Systems: Machines combining cutting, bending, and shaping in one unit.

Conclusion

Bar Cutting Machines are a cornerstone of modern construction in Bawana. They improve accuracy, efficiency, and safety while reducing labor and material waste. From manual cutters to advanced CNC models, choosing the right machine ensures that construction projects run smoothly and cost-effectively.

For product details, visit: Bar Cutting Machine

For insights on efficiency and performance: Bar Cutting Machine Enhancing Precision and Efficiency in Light Construction

For latest types and innovations: Introducing the Latest Bar Cutting Machines for Efficient Construction

By using Bar Cutting Machines, construction projects in Bawana can achieve higher productivity, better precision, and improved safety.