Ramandeep Singh / Date: 12 Feb, 2026

Bar Cutting Machines: A Comprehensive Guide to Industrial Cutting Solutions

In modern manufacturing and construction industries, precision and efficiency are paramount. Bar cutting machine have emerged as essential equipment for businesses dealing with steel reinforcement bars, metal rods, and various bar materials. These powerful tools transform raw bar stock into precisely cut pieces, enabling faster production cycles and superior quality control.

Whether you're working with steel rebar for construction projects or cutting metal bars for manufacturing applications, understanding bar cutting machines is crucial for optimizing your operations. This comprehensive guide explores everything you need to know about these indispensable industrial tools.

Bar cutting machines come in various configurations, each designed for specific applications and materials. Manual bar cutters represent the most basic type, requiring operator force to cut through bars. These are suitable for small-scale operations or occasional cutting needs where investment in automated equipment isn't justified.

Semi-automatic bar cutting machines offer a middle ground between manual and fully automated systems. These machines typically feature motorized cutting mechanisms but require manual material feeding and positioning. They're ideal for medium-scale operations that need consistent cuts without the complexity of full automation.

Fully automatic bar cutting machines represent the pinnacle of cutting technology. These sophisticated systems handle material feeding, measurement, cutting, and sometimes even sorting with minimal human intervention. Leading bar cutting machine manufacturers have developed these systems to process hundreds of cuts per hour with remarkable precision.

Hydraulic bar cutters use fluid pressure to generate cutting force, making them excellent for heavy-duty applications involving thick bars and hard materials. Electric bar cutting machines, conversely, rely on motor-driven mechanisms and are often preferred for their energy efficiency and lower maintenance requirements.

Portable bar cutting machines provide mobility for on-site applications, particularly valuable in construction environments where materials need to be cut at various locations. Stationary models offer greater stability and are typically more powerful, making them the choice for workshop and factory settings.

When evaluating bar cutting machines, cutting capacity stands as the primary consideration. This specification indicates the maximum diameter and type of material the machine can handle. Reputable bar cutting machine suppliers provide detailed capacity charts showing performance across different material grades.

Cutting precision directly impacts material waste and project quality. Modern machines achieve tolerances within millimeters, ensuring each piece meets exact specifications. Look for models featuring adjustable cutting angles, as this versatility enables both straight and angled cuts without requiring multiple machines.

Automation level significantly affects productivity. Advanced models feature programmable length settings, automatic feeding systems, and batch cutting capabilities that dramatically reduce labor requirements. The control interface should be intuitive, allowing operators to quickly set parameters and monitor operations.

Motor power and blade quality determine cutting speed and longevity. High-torque motors maintain consistent performance even with tough materials, while premium-grade blades or shearing mechanisms ensure clean cuts and extended service life. Many bar cutting machine manufacturers now incorporate safety features like blade guards, emergency stops, and two-hand operation controls as standard equipment.

Build quality and frame construction affect durability and cutting accuracy. Heavy-duty steel frames minimize vibration and maintain alignment during operation. Consider machines with easily replaceable wear parts, as this feature reduces long-term maintenance costs and downtime.

The efficiency gains from steel bar cutting machines are substantial. What might take hours with manual cutting methods can be accomplished in minutes with modern equipment. This time savings translates directly into increased production capacity and faster project completion.

Precision cutting reduces material waste significantly. When every cut meets exact specifications, there's no need for rework or scrap due to measurement errors. Over time, these savings in raw material costs can offset the initial equipment investment.

Consistency is another major advantage that bar cutting machine suppliers emphasize. Automated systems produce identical cuts repeatedly, ensuring uniformity across large production runs. This consistency is particularly valuable in manufacturing environments where components must meet strict tolerances.

Worker safety improves dramatically when dangerous manual cutting operations are mechanized. Modern machines incorporate multiple safety features that protect operators while maintaining high productivity. The reduction in physical strain also leads to fewer workplace injuries and improved employee satisfaction.

Labor cost reduction represents a significant long-term benefit. A single operator can manage automated cutting operations that would otherwise require multiple workers. This efficiency allows businesses to reallocate human resources to higher-value activities.

Quality improvement extends beyond mere cutting accuracy. Clean, precise cuts reduce the need for secondary finishing operations, streamlining the production process. The professional appearance of machine-cut components also enhances the final product's marketability.

Selecting the appropriate bar cutting machine begins with a thorough assessment of your operational requirements. Calculate your daily or weekly cutting volume to determine whether manual, semi-automatic, or fully automatic equipment makes economic sense. Consider not just current needs but anticipated growth, as investing in slightly larger capacity can prevent premature replacement.

Material specifications are equally critical. Different bar cutting machine manufacturers specialize in various material types and sizes. Ensure the machine you select handles your specific bar diameters, material grades, and any special alloys you work with. Verify cutting capacity specifications with actual samples when possible.

Space constraints in your facility may dictate machine size and configuration. Measure available floor space carefully, accounting for material storage areas, operator access, and safety clearances. Portable models offer flexibility if you need to move equipment between locations or have limited permanent workspace.

Budget considerations extend beyond the purchase price. Factor in installation costs, electrical requirements, operator training, and ongoing maintenance expenses. While premium machines from established bar cutting machine suppliers command higher prices, their reliability and efficiency often justify the investment through reduced downtime and maintenance costs.

Technical support and parts availability are frequently overlooked factors that become critical when equipment needs service. Choose manufacturers or suppliers with proven track records for customer support, readily available spare parts, and comprehensive warranty coverage.

Integration with existing workflows should also influence your decision. Some advanced machines can connect to production management systems, enabling better scheduling and quality tracking. Consider whether such features would benefit your operations.

Regular maintenance is essential for maximizing equipment lifespan and maintaining cutting precision. Daily inspection routines should include checking blade condition, verifying that all safety guards are properly positioned, and clearing any material debris from the cutting area. These simple checks take only minutes but prevent many common problems.

Lubrication schedules vary by machine type, but most require regular application of appropriate lubricants to moving parts, guides, and hydraulic components. Consult the manufacturer's maintenance manual for specific intervals and product recommendations. Using incorrect lubricants can cause premature wear or component failure.

Blade maintenance deserves special attention, as cutting quality depends directly on blade condition. Monitor for signs of dulling such as increased cutting resistance, rougher cut surfaces, or material deformation. Sharpening or replacing blades promptly maintains cutting quality and reduces strain on other machine components.

Hydraulic systems in powered bar cutters require periodic fluid level checks and filter replacements. Contaminated hydraulic fluid can damage pumps and cylinders, leading to expensive repairs. Many bar cutting machine manufacturers recommend fluid analysis at specific intervals to detect potential problems early.

Electrical connections and control systems benefit from regular inspection to identify loose wires, worn cables, or corrosion. Keeping electrical components clean and secure prevents unexpected shutdowns and safety hazards. Annual professional inspections by qualified technicians can identify issues before they cause breakdowns.

Record keeping helps track maintenance history and identify patterns that might indicate developing problems. Documenting blade changes, fluid replacements, and any repairs creates valuable data for predicting future maintenance needs and budgeting for parts and service.

Operator training forms the foundation of safe bar cutting machine operation. Even experienced workers need proper instruction on specific machine models, as features and controls vary between manufacturers. Comprehensive training should cover normal operation, emergency procedures, and basic troubleshooting.

Personal protective equipment is mandatory when operating cutting machinery. Safety glasses protect against metal chips and debris, while hearing protection guards against noise exposure from powerful motors and cutting operations. Gloves should be avoided during actual cutting operations to prevent entanglement hazards, though they're appropriate for material handling.

Material handling procedures require careful attention, particularly with heavy or awkward bar stock. Use proper lifting techniques and mechanical aids when positioning materials. Ensure bars are securely positioned before initiating cuts, as movement during cutting can cause blade damage or dangerous material ejection.

Machine guarding must never be bypassed or removed during operation. Bar cutting machine suppliers design guards specifically to protect operators from moving parts and flying debris. Operating equipment with disabled safety features violates both workplace regulations and common sense.

Emergency stop controls should be clearly identified and tested regularly. Every operator must know the exact location of emergency stops and how to activate them instantly. Regular drills help ensure automatic responses in crisis situations.

Maintenance lockout procedures prevent accidental machine activation during servicing. Before performing any maintenance, disconnect power sources, engage lockout devices, and verify that the machine cannot be started. These procedures protect maintenance personnel from potentially fatal injuries.

Uneven or rough cuts often indicate blade problems. Dull, damaged, or improperly installed blades produce poor cutting quality. Inspect the blade for wear, chips, or misalignment. Replace worn blades immediately rather than forcing them to continue cutting, as this damages other machine components.

Machine jamming typically results from material movement during cutting, attempting to cut oversized stock, or mechanical obstructions. If jamming occurs, shut down the machine immediately and identify the cause before resuming operation. Never attempt to clear jams while the machine is running.

Hydraulic system problems manifest as slow operation, loss of cutting force, or unusual noises. Check fluid levels first, as low fluid is the most common cause of hydraulic issues. Examine hoses and connections for leaks, and verify that filters aren't clogged. Experienced bar cutting machine manufacturers design their systems for easy troubleshooting with clear diagnostic procedures.

Electrical issues may present as intermittent operation, failure to start, or control system errors. Verify that power connections are secure and circuit breakers haven't tripped. Check for error codes or warning lights that indicate specific problems. Many modern machines include diagnostic displays that identify issues precisely.

Accuracy drift develops gradually as machines age and components wear. Regular calibration checks using precision measuring tools help detect accuracy problems early. Most machines include adjustment procedures for correcting alignment and ensuring cuts meet specifications.

Unusual vibration or noise signals mechanical problems requiring immediate attention. Loose bolts, worn bearings, or damaged components can create vibrations that worsen rapidly if ignored. Address these symptoms promptly to prevent major damage.

Digital controls and programmable features represent significant advances in rebar cutting machine technology. Modern systems allow operators to store cutting programs for different products, reducing setup time and eliminating measurement errors. Touchscreen interfaces make programming intuitive even for operators with limited technical experience.

Servo motor technology delivers superior cutting precision and energy efficiency compared to traditional systems. These advanced motors provide exact speed and position control, enabling cleaner cuts and longer blade life. Leading bar cutting machine manufacturers increasingly incorporate servo technology across their product lines.

Automated material handling systems integrate with cutting machines to create complete processing solutions. Automatic feeders supply bar stock continuously, while sorting systems organize cut pieces by length or destination. These integrated systems minimize manual handling and maximize throughput.

Remote monitoring capabilities allow operators and maintenance teams to track machine performance from anywhere. Cloud-connected systems provide real-time status updates, maintenance alerts, and production data analytics. This connectivity enables predictive maintenance strategies that reduce unplanned downtime.

Enhanced safety features continue evolving with technology. Light curtains detect operator presence near dangerous areas, automatically stopping the machine if someone enters the hazard zone. Advanced two-hand controls ensure operators maintain safe positions during cutting cycles.

Energy efficiency improvements reduce operating costs and environmental impact. Variable frequency drives optimize motor speed for different cutting tasks, consuming electricity only as needed. Bar cutting machine suppliers increasingly market energy savings as a key benefit alongside productivity improvements.

Artificial intelligence and machine learning are beginning to influence bar cutting technology. Smart systems can adjust cutting parameters automatically based on material characteristics, predict optimal blade replacement timing, and identify patterns that indicate developing problems.

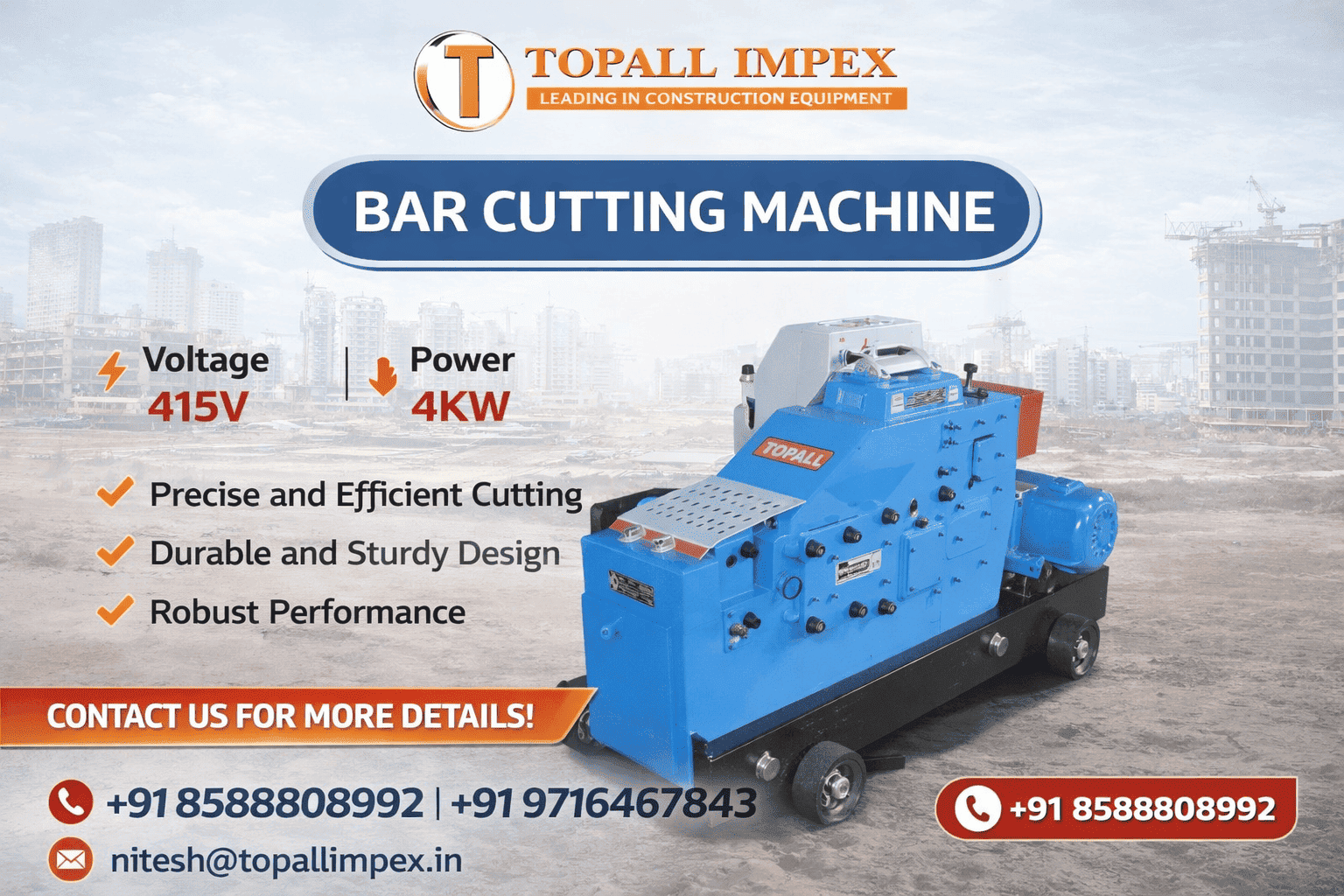

Topall Impex has established itself as a trusted partner for businesses seeking reliable bar cutting solutions. With years of experience in the industrial equipment sector, the company understands the unique challenges faced by manufacturers and construction professionals.

The comprehensive product range offered by Topall Impex covers all categories of bar cutting machines, from compact portable units to high-capacity production systems. This diversity ensures clients can find equipment precisely matched to their requirements without compromise.

Quality assurance stands central to Topall Impex's business philosophy. Every machine undergoes rigorous testing before delivery, ensuring it meets performance specifications and safety standards. The company partners with reputable bar cutting machine manufacturers known for engineering excellence and durability.

Technical support sets Topall Impex apart from typical equipment suppliers. The experienced technical team provides expert guidance during the selection process, helping clients identify the optimal solution for their specific applications. Post-sale support includes installation assistance, operator training, and ongoing technical consultation.

Spare parts availability ensures minimal downtime when maintenance or repairs become necessary. Topall Impex maintains comprehensive parts inventory for all supplied equipment, enabling rapid fulfillment of service requirements. This commitment to after-sales support protects clients' investments and operational continuity.

Competitive pricing without compromising quality makes Topall Impex an attractive choice for budget-conscious buyers. The company's relationships with manufacturers and efficient operations enable cost advantages that benefit customers through fair pricing on premium equipment.

Customer-centric service philosophy drives every interaction at Topall Impex. The team takes time to understand each client's unique situation, offering personalized recommendations rather than pushing predetermined solutions. This consultative approach builds long-term relationships based on trust and mutual success.

Bar cutting machines represent critical investments for businesses in manufacturing, construction, and metal fabrication industries. The right equipment dramatically improves productivity, quality, and safety while reducing labor costs and material waste. Understanding the various machine types, features, and applications enables informed decisions that align equipment capabilities with operational needs.

Proper selection requires careful assessment of cutting requirements, material specifications, production volumes, and budget constraints. Working with experienced bar cutting machine suppliers like Topall Impex provides access to expert guidance and quality equipment backed by reliable support services.

Maintenance and safety practices are equally important as equipment selection. Regular servicing preserves machine performance and extends operational life, while rigorous safety protocols protect workers and ensure regulatory compliance. Staying informed about technological innovations helps businesses remain competitive as cutting technology continues advancing.

The efficiency gains from modern bar cutting machines compound over time, delivering returns that far exceed initial investment costs. By reducing manual labor, minimizing waste, and improving cut quality, these machines become profit centers rather than mere expense items. Businesses that embrace cutting technology position themselves for growth and success in increasingly competitive markets.

Making the commitment to quality equipment from reputable bar cutting machine manufacturers, supported by dedicated suppliers, sets the foundation for operational excellence. With proper selection, installation, training, and maintenance, bar cutting machines deliver years of reliable service that powers business success.

Trusted by leading brands and businesses across industries

Nowadays, the bar cutting machine has become one of the essential tools on the construction site, as..

Amongst the very vital tools both in construction and landscaping activities are plate compactors. W..

Machines used in polishing concrete find very wide application in modern construction and interior: ..

There are a range of construction machines but the most underrated among them is the Rebar Processin..

There is a variety of uses in the use of advanced equipment, ranging from concrete mixers to pumps a..

Toyo machines have ranked high as far as quality and efficient machinery is concerned in the constru..

Speed, accuracy and life span are the keys to success in the construction and infrastructure industr..

In construction business, the factors present in successful business entails safety, speed, and savi..

In the construction industry contractors are ever faced with pressure to deliver quality ..

Introduction The construction business has experienced an enormous change over the recent decades. ..

Introduction In the world of modern construction, time, precision, and safety play a crucial role i..

Throughout the construction sector, accuracy and productivity are not only welcome attributes but al..

Construction is an industry in which precision, stability, and performance determine the standards o..

In the current fast developing field of construction, efficiency and accuracy is the key to success...

In the modern construction industry, speed, accuracy, and efficiency are critical factors that deter..

Introduction Construction work demands precision, stability, and durability at every stage. Before ..

Introduction Construction technology has advanced rapidly, especially in the high-rise building sec..

Introduction In today’s competitive construction industry, efficiency and accuracy are non-ne..

Introduction Construction industry is among the most significant industries in the worldwide develo..

Introduction In the construction industry, steel reinforcement plays a vital role in ensuring the s..

Introduction – The Importance of Surface Preparation The construction and flooring industries..

Introduction In today’s fast-paced construction industry, efficiency, accuracy, and safety ar..

Concrete finishing is one of the most critical stages in any construction project. Achieving smooth,..

Modern construction demands tools that combine precision, efficiency, and safety. One essential piec..

Introduction India’s construction industry is experiencing unprecedented growth. With rapid u..

Introduction Modern construction projects demand efficiency, precision, and safety. One of the most..

Introduction In modern construction, the quality of road surfaces depends heavily on proper compact..

Construction projects today require a combination of efficiency, precision, and safety. The introduc..

Introduction: Rising Demand in Construction India’s construction sector is advancing at a rem..

Introduction: Advancing Construction with Modern Machinery Bar bending machines are transforming In..

A Bar Bending Machine is a crucial tool in construction, helping workers bend steel rebars effi..

Introduction In modern construction, efficiency, safety, and precision are essential. Among the wid..

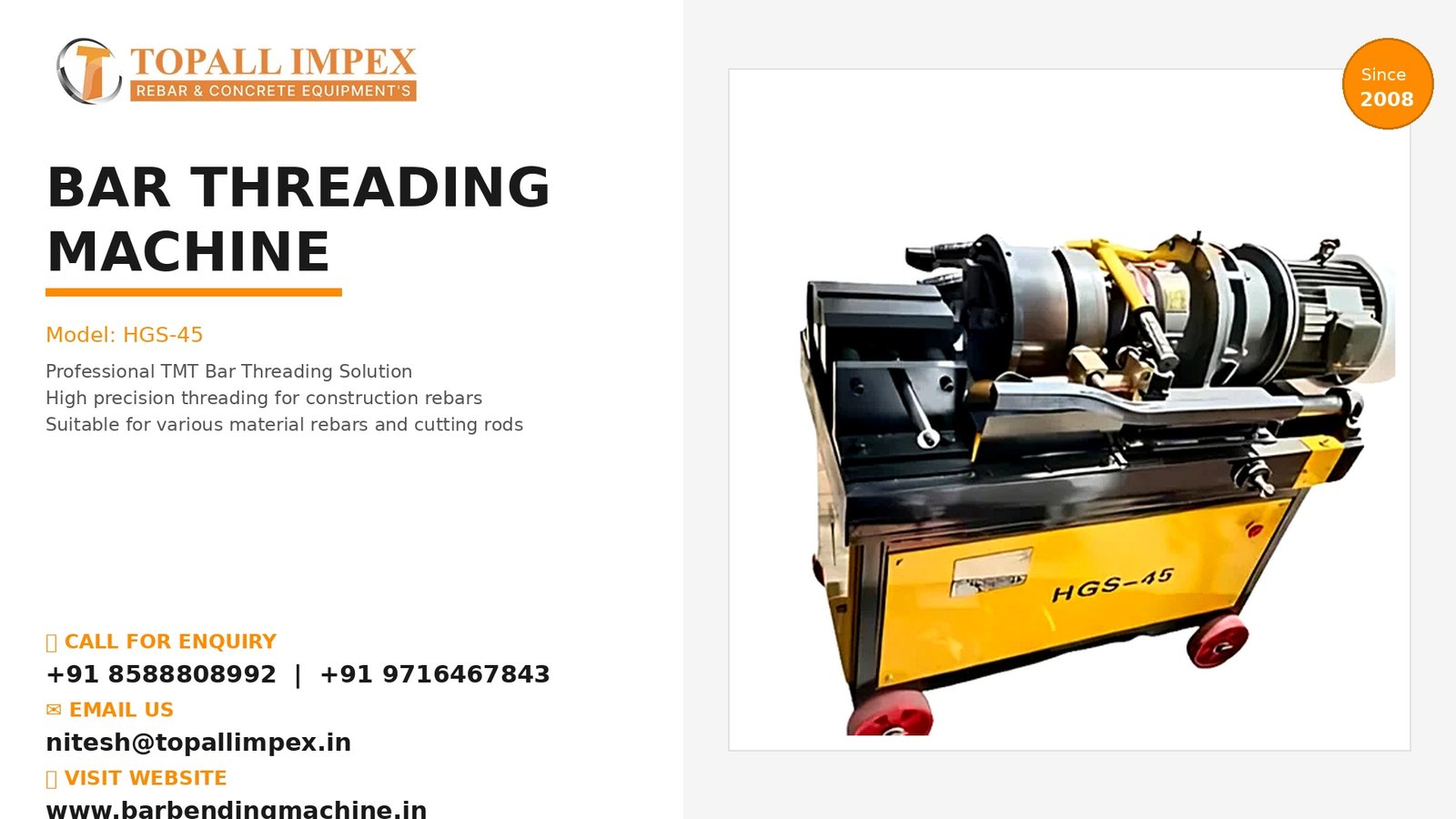

Introduction The Rebar Threading Machine is an essential tool for modern construction, designed to ..

Best Places to Buy Bar Bending Machines Near Me – By Topall Impex When it comes to modern con..

In today’s fast-paced construction industry, efficiency, precision, and durability are essenti..

In the modern construction industry, efficiency, precision, and reliability are non-negotiable. One ..

In modern construction, efficiency, precision, and durability are crucial for completing projects on..

In the booming construction industry of India, efficiency, precision, and cost-effectiveness are cru..

In the fast-growing construction sector of India, bar bending machines are indispensable for efficie..

In India’s fast-paced construction industry, time is money. Contractors, builders, and infrast..

In India’s growing construction sector, every project demands precision, efficiency, and relia..

In India’s rapidly growing construction sector, bar bending machines are essential for shaping..

In India’s booming construction industry, bar bending machines are indispensable for efficient..

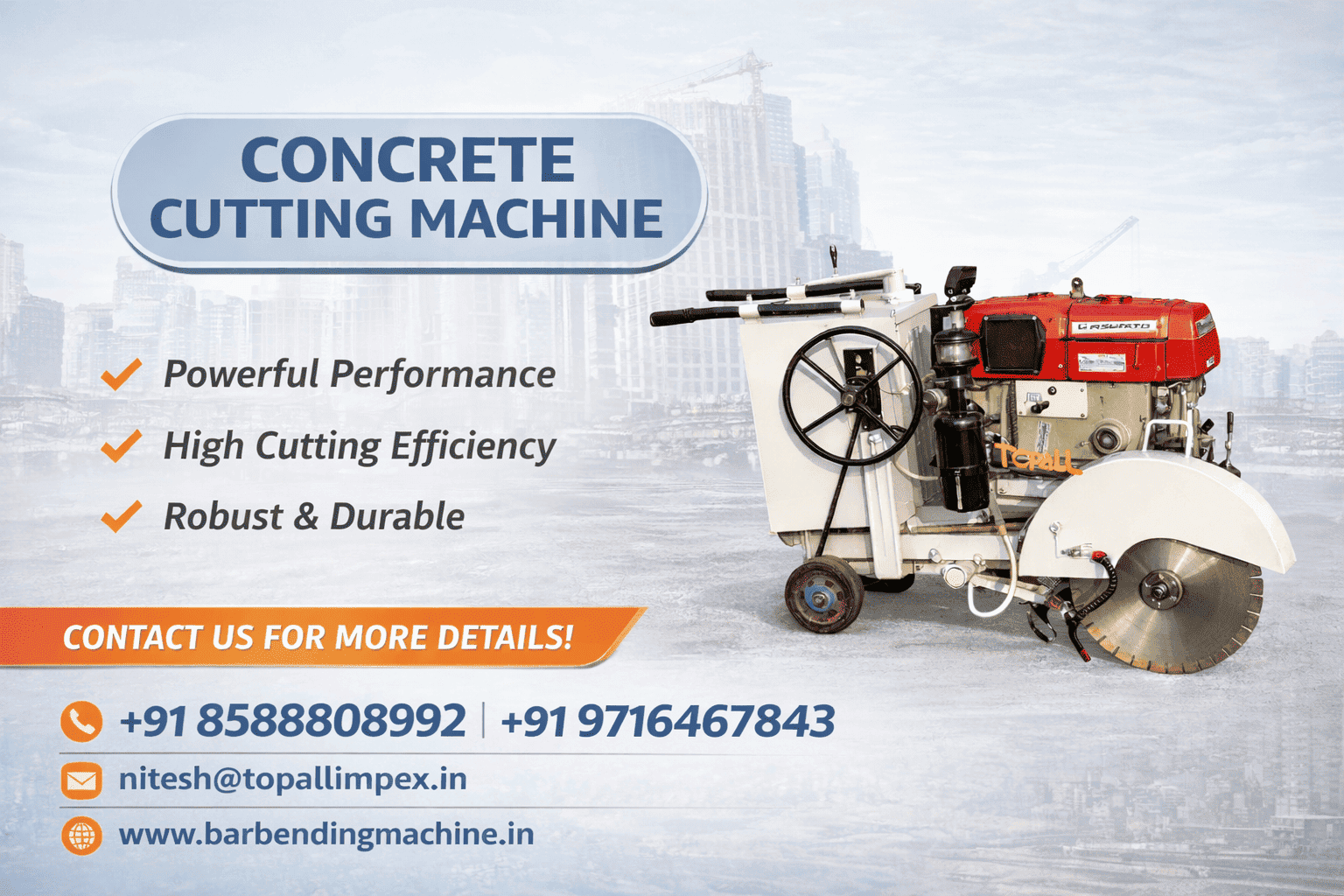

When precision meets power in construction, concrete cutting machines become indispensable. Whether ..

Bar Threading Machine: The Complete Guide to Precision Threading Solutions In modern construction a..