/ Date: 12 Feb, 2026

When precision meets power in construction, concrete cutting machines become indispensable. Whether you're working on highway expansion, building renovation, or demolition projects, understanding these machines can make the difference between a smooth operation and costly delays.

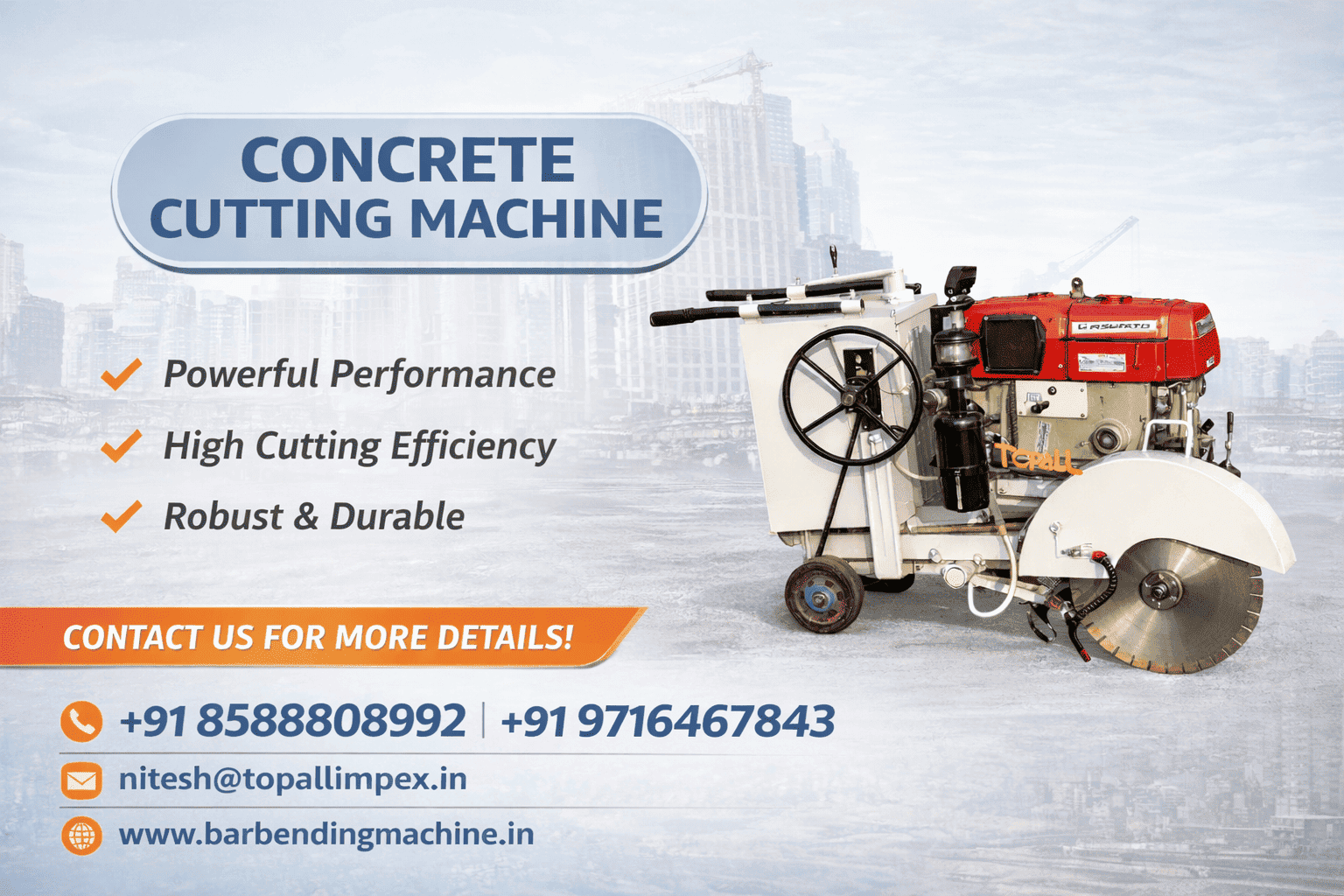

A concrete cutting machine is a specialized power tool designed to cut through reinforced concrete, asphalt, stone, and other hard materials with precision. Unlike traditional breaking methods, these machines create clean, accurate cuts without causing structural damage to surrounding areas. Modern concrete cutting equipment comes in various types—from handheld saws for small jobs to walk-behind and wall-mounted systems for industrial applications.

The technology has evolved significantly over the past decades. Today's machines combine diamond-tipped blades with hydraulic or electric power systems, delivering cuts that would have been impossible with manual methods. Both concrete cutting machine manufacturers and concrete cutting machine suppliers now offer solutions ranging from compact 12-inch blade models to heavy-duty machines capable of cutting depths exceeding 30 inches.

Choosing the right equipment requires careful evaluation. The blade diameter determines your maximum cutting depth—a 14-inch blade typically cuts up to 5 inches deep, while larger industrial models with 36-inch blades can penetrate over a foot. Power source matters equally. Electric motors work well for indoor jobs with minimal dust, while gasoline or diesel engines provide mobility for outdoor projects.

Weight and portability often get overlooked until you need to transport equipment between floors or tight spaces. Handheld models weigh between 20 to 40 pounds, manageable for one operator, whereas walk-behind units can exceed 500 pounds and require loading equipment. Cutting speed, measured in RPM (revolutions per minute), affects both efficiency and finish quality. Professional-grade machines maintain consistent speeds between 4,000 to 5,500 RPM regardless of load.

Water delivery systems prevent blade overheating and suppress dust. Look for machines with adjustable flow rates and easy-to-refill tanks. Reputable concrete cutting machine manufacturers integrate safety features like blade guards, anti-kickback mechanisms, and vibration dampening systems that reduce operator fatigue during extended use.

Precision stands as the primary advantage. These machines create straight cuts with tolerances within millimeters, essential for creating doorways, windows, or expansion joints. Traditional jackhammering creates irregular edges requiring additional finishing work, adding time and labor costs.

Controlled cutting minimizes structural stress. When removing concrete sections, vibration-free cutting prevents microfractures in adjacent areas. This becomes critical in renovation projects where maintaining existing structural integrity is non-negotiable. The clean cuts also eliminate the need for extensive patching and refinishing.

Speed dramatically improves project timelines. What might take a crew several days with manual methods can be completed in hours with the right concrete cutting equipment. This efficiency translates directly to reduced labor costs and faster project completion. Additionally, modern machines produce significantly less noise than traditional breaking methods, making them suitable for urban environments with strict noise regulations.

Versatility extends their value. The same machine that cuts concrete also handles asphalt, brick, stone, and tile with appropriate blade changes. This multi-material capability reduces the need for multiple specialized tools on job sites.

Urban infrastructure projects represent the largest application area. Road repairs, sidewalk installations, and utility line access all require precise concrete cutting. Cities expanding their metro systems rely on these machines to create access points without disrupting existing structures.

Commercial construction uses concrete cutting for creating openings in existing buildings during renovations or additions. Retailers expanding their spaces, hospitals adding wings, and office buildings undergoing modernization all depend on accurate cutting to maintain structural safety while modifying floor plans.

Industrial facilities employ concrete cutting machines for maintenance and modifications. Manufacturing plants updating equipment layouts, warehouses expanding loading docks, and processing facilities adding new production lines need clean, precise cuts that don't compromise floor integrity or create extended downtime.

Residential applications include basement waterproofing, pool installations, and home additions. Contractors creating egress windows for basement conversions or cutting foundation walls for additions require equipment that delivers professional results without excessive mess or structural disruption.

Highway and road construction demands the toughest concrete cutting equipment available. Walk-behind self-propelled saws with 36 to 48-inch diameter blades cut through reinforced concrete pavement up to 18 inches thick. These machines feature heavy-duty frames, often weighing over 1,000 pounds, to maintain stability during deep cutting operations.

Modern road-cutting machines incorporate advanced features specifically for heavy-duty work. Variable speed control allows operators to adjust cutting speeds based on concrete hardness and rebar density. Laser-guided systems ensure perfectly straight cuts over extended distances—critical when creating expansion joints that may run hundreds of feet.

Concrete cutting machine suppliers serving the road construction sector provide machines with diesel engines ranging from 20 to 65 horsepower. This power handles the continuous operation required for highway projects while maintaining consistent cutting depth regardless of material variations. Water systems on these units circulate dozens of gallons per minute to keep blades cool during hours of continuous cutting.

Specialized attachments convert standard road saws into multi-functional tools. Scarifiers remove deteriorated concrete layers, grooving heads create anti-slip textures, and joint-cleaning attachments prepare surfaces for sealing. This versatility makes heavy-duty concrete cutting machines central to comprehensive road maintenance programs.

Recognizing blade wear prevents compromised cut quality and potential safety hazards. Visible diamond segment reduction is the most obvious indicator. New blades have segments extending several millimeters above the blade core. When segments wear to within 2-3 millimeters, cutting efficiency drops significantly, and blade failure risk increases.

Cutting speed reduction signals blade deterioration. If your machine takes noticeably longer to complete cuts that previously took less time, dulled or damaged diamond segments are likely responsible. This inefficiency not only slows work but increases wear on the machine's drive system.

Unusual vibration during cutting indicates uneven blade wear or segment loss. A properly maintained blade runs smoothly with minimal vibration. Excessive shaking can damage the equipment's spindle bearings and creates dangerous working conditions for operators.

Visual damage like cracks in the blade core, missing segments, or warped blades requires immediate replacement. Operating with damaged blades risks catastrophic failure that could cause serious injury. Professional contractors inspect blades before each use and maintain replacement inventory to avoid project delays.

Proper maintenance begins with cleanliness. Concrete dust and slurry accumulation accelerates wear on moving parts and can clog cooling systems. After each use, thoroughly clean the machine with water, paying special attention to air vents, water channels, and blade guard areas. For electric models, ensure complete drying before storage to prevent moisture-related electrical issues.

Blade care directly impacts machine longevity. Use appropriate blades for specific materials—diamond blades rated for reinforced concrete differ from those designed for asphalt or masonry. Operating with incorrect blades forces the motor to work harder, shortening its lifespan. Maintain proper cutting speed and avoid forcing cuts, which can bind blades and strain drive systems.

Regular inspection catches problems before they become failures. Check drive belts monthly for cracks or glazing, replace worn belts promptly to prevent sudden breakdowns during critical cuts. Examine water pump seals for leaks, as pump failure stops operations completely. Lubricate all moving parts according to manufacturer specifications—over-lubrication attracts dust buildup, while under-lubrication accelerates wear.

Proper storage protects your investment. Store machines in dry, covered locations away from extreme temperature fluctuations. For gasoline-powered units, drain fuel before extended storage to prevent carburetor varnish buildup. Keep machines elevated off concrete floors to prevent moisture absorption that can corrode metal components.

Operator training reduces misuse-related damage. Even high-quality equipment from leading concrete cutting machine manufacturers won't survive repeated operator errors. Train all personnel on proper starting procedures, cutting techniques, and shutdown protocols. Document training to ensure consistent practices across crews.

Demolition cutting prioritizes speed and accessibility over finish quality. When removing entire sections of a building, contractors use larger, more aggressive blades that cut quickly through heavily reinforced concrete. Safety concerns focus on structural stability during cutting—ensuring partial cuts don't compromise remaining structures before planned collapse.

Demolition projects often involve cutting in hazardous environments with limited access. Wall-mounted track systems allow cutting through vertical surfaces from one side, essential when the opposite side is inaccessible or unsafe. Contractors may work around damaged rebar, broken concrete, or unstable surfaces, requiring equipment with enhanced safety features and operator protection.

Construction cutting demands precision and clean edges. Creating doorway openings or expansion joints requires cuts accurate to within millimeters, as these openings will receive finished frames or sealants. The surrounding concrete must remain undamaged, so slower cutting speeds with continuous water flow prevent thermal stress and microcracking.

Construction environments typically provide better access and working conditions. Operators work from stable platforms with adequate lighting and power supply. Projects follow detailed plans specifying exact cutting locations, depths, and angles. Quality control inspections verify cut accuracy before subsequent construction phases begin.

Equipment selection reflects these differences. Demolition contractors prefer rugged, gasoline-powered machines capable of withstanding harsh conditions and providing maximum portability. Construction applications favor electric models for their clean operation, precise speed control, and lower noise levels in occupied or partially completed buildings.

Smart city development requires extensive infrastructure modifications to accommodate sensor networks, fiber optic cables, and electric vehicle charging stations. Concrete cutting machines enable precise integration of these systems into existing urban landscapes without extensive demolition and reconstruction.

Underground utility installation for smart grids demands accurate trench cutting through city streets and sidewalks. Modern concrete cutting equipment creates narrow, precise cuts that minimize surface disruption and speed restoration. This precision reduces the urban impact of infrastructure upgrades, allowing cities to modernize with less inconvenience to residents and businesses.

Adaptive infrastructure represents another smart city application. As urban needs change, buildings and public spaces require modifications. Concrete cutting technology allows rapid reconfiguration of spaces—converting loading zones to pedestrian areas, adding bike lanes, or installing street-level data hubs. The speed and precision of modern cutting equipment make these adaptive changes economically viable.

Sustainable construction practices in smart cities benefit from concrete cutting's efficiency. Selective cutting allows preservation and reuse of existing concrete structures rather than complete demolition. This reduces construction waste, lowers carbon footprint from new concrete production, and accelerates project timelines—all priorities in sustainable urban development.

Small residential projects involving single cuts or occasional use suit handheld cutters with 12 to 14-inch blades. These machines handle cutting depths up to 5 inches, sufficient for creating small openings, cutting tile, or making shallow trenches. Their lightweight design and lower cost make them practical for contractors who don't specialize in concrete cutting but occasionally need the capability.

Medium commercial projects with regular cutting requirements benefit from walk-behind saws in the 18 to 24-inch blade range. These mid-size machines cut depths between 7 to 9 inches and provide better stability for longer cuts. They represent the sweet spot for commercial contractors handling renovation work, retail build-outs, and light industrial applications.

Large industrial and infrastructure projects demand heavy-duty walk-behind or track-mounted systems with blades exceeding 30 inches. These machines cut through thick reinforced concrete slabs and handle continuous operation required for highway work or major demolition projects. The significant investment makes sense only for contractors with consistent large-scale project volumes.

Project frequency also influences selection. Occasional users may find renting from concrete cutting machine suppliers more economical than purchasing. Frequent users should invest in quality equipment from established concrete cutting machine manufacturers, as rental costs quickly exceed purchase prices for regular use.

Reliability tops every professional's priority list. Contractors can't afford equipment failures during critical cuts. They seek machines from manufacturers with proven track records, extensive dealer networks for parts availability, and responsive technical support. Equipment downtime directly impacts project schedules and profitability.

Power-to-weight ratio affects both performance and operator fatigue. Professional-grade machines maximize cutting power while minimizing unnecessary weight. Advanced materials and engineering create tools that deliver industrial performance without requiring two operators or mechanical assistance for positioning.

Blade mounting systems that allow quick changes save valuable time. Professionals often switch between blades for different materials or cutting depths multiple times daily. Tool-less blade changes or simplified mounting systems reduce changeover time from fifteen minutes to under five.

Comprehensive safety features protect both operators and liability exposure. Professional contractors examine blade guards, anti-kickback systems, water delivery reliability, and ergonomic handle design. Equipment-related injuries create financial and legal consequences beyond immediate medical costs.

Dealer support and parts availability influence long-term satisfaction. Contractors prefer brands with local dealers who stock common replacement parts and provide maintenance services. The ability to get parts same-day or next-day prevents extended downtime that can delay projects and damage client relationships.

Resale value matters for contractors who upgrade equipment regularly. Established brands from recognized concrete cutting machine manufacturers retain value better than lesser-known alternatives. This residual value offsets upgrade costs and makes equipment investment more financially sustainable.

Topall Impex stands as Delhi's leading concrete cutting machine manufacturer and supplier since 2008, bringing over 16 years of trusted expertise to the construction industry. Based in Delhi, we offer a comprehensive range of cutting equipment—from handheld cutters to heavy-duty road saws—all manufactured to international quality standards with diamond-grade blades, high-efficiency motors, and advanced safety features. Our strategic location enables rapid pan-India delivery and same-day service for Delhi NCR clients, while our direct manufacturer pricing eliminates middleman costs without compromising quality. What truly sets us apart is our complete after-sales ecosystem: expert technical support, operator training, readily available genuine spare parts, maintenance services, and customization capabilities tailored to your specific project needs. Serving diverse sectors including highway construction, commercial contractors, government agencies, and industrial facilities, we've built lasting partnerships with thousands of satisfied customers who trust our commitment to innovation, environmental responsibility, and unwavering reliability. At Topall Impex, we don't just sell machines—we invest in your success with equipment that delivers precision in every cut and a partnership you can depend on for years to come.

Understanding concrete cutting machines transforms them from mysterious industrial tools into practical solutions for construction challenges. Whether you're a contractor evaluating equipment purchases or a project manager planning infrastructure work, the information above provides the foundation for informed decisions.

The concrete cutting industry continues evolving with technological improvements in blade materials, power systems, and precision controls. Staying informed about these developments through reputable concrete cutting machine suppliers and industry publications ensures you're equipped with knowledge to select tools that deliver results today and adapt to tomorrow's demands.

Quality equipment, proper maintenance, and skilled operation combine to make concrete cutting a precise, efficient, and safe construction process. The investment in understanding these machines pays returns through faster project completion, superior results, and safer job sites.

Trusted by leading brands and businesses across industries

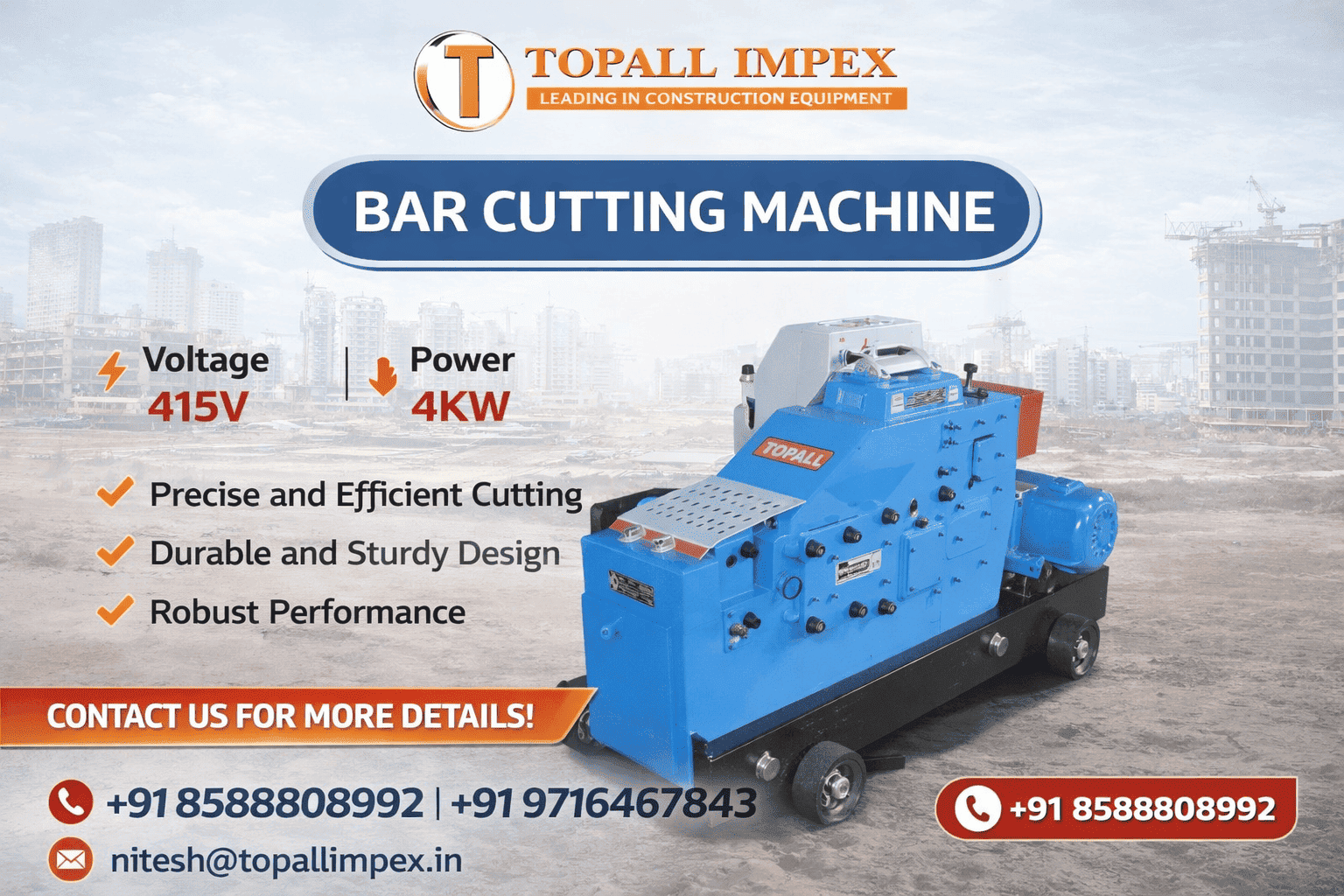

Nowadays, the bar cutting machine has become one of the essential tools on the construction site, as..

Amongst the very vital tools both in construction and landscaping activities are plate compactors. W..

Machines used in polishing concrete find very wide application in modern construction and interior: ..

There are a range of construction machines but the most underrated among them is the Rebar Processin..

There is a variety of uses in the use of advanced equipment, ranging from concrete mixers to pumps a..

Toyo machines have ranked high as far as quality and efficient machinery is concerned in the constru..

Speed, accuracy and life span are the keys to success in the construction and infrastructure industr..

In construction business, the factors present in successful business entails safety, speed, and savi..

In the construction industry contractors are ever faced with pressure to deliver quality ..

Introduction The construction business has experienced an enormous change over the recent decades. ..

Introduction In the world of modern construction, time, precision, and safety play a crucial role i..

Throughout the construction sector, accuracy and productivity are not only welcome attributes but al..

Construction is an industry in which precision, stability, and performance determine the standards o..

In the current fast developing field of construction, efficiency and accuracy is the key to success...

In the modern construction industry, speed, accuracy, and efficiency are critical factors that deter..

Introduction Construction work demands precision, stability, and durability at every stage. Before ..

Introduction Construction technology has advanced rapidly, especially in the high-rise building sec..

Introduction In today’s competitive construction industry, efficiency and accuracy are non-ne..

Introduction Construction industry is among the most significant industries in the worldwide develo..

Introduction In the construction industry, steel reinforcement plays a vital role in ensuring the s..

Introduction – The Importance of Surface Preparation The construction and flooring industries..

Introduction In today’s fast-paced construction industry, efficiency, accuracy, and safety ar..

Concrete finishing is one of the most critical stages in any construction project. Achieving smooth,..

Modern construction demands tools that combine precision, efficiency, and safety. One essential piec..

Introduction India’s construction industry is experiencing unprecedented growth. With rapid u..

Introduction Modern construction projects demand efficiency, precision, and safety. One of the most..

Introduction In modern construction, the quality of road surfaces depends heavily on proper compact..

Construction projects today require a combination of efficiency, precision, and safety. The introduc..

Introduction: Rising Demand in Construction India’s construction sector is advancing at a rem..

Introduction: Advancing Construction with Modern Machinery Bar bending machines are transforming In..

A Bar Bending Machine is a crucial tool in construction, helping workers bend steel rebars effi..

Introduction In modern construction, efficiency, safety, and precision are essential. Among the wid..

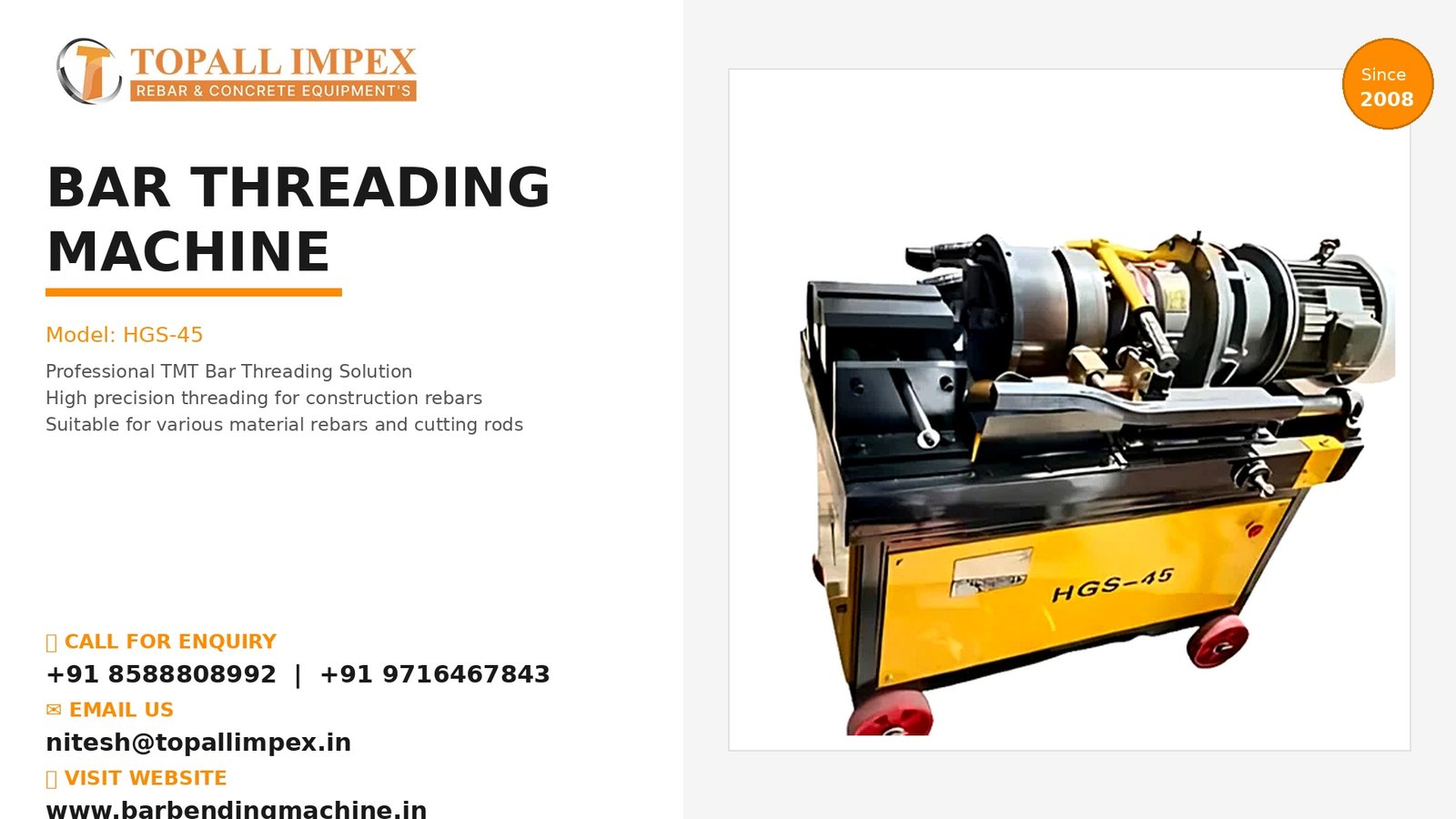

Introduction The Rebar Threading Machine is an essential tool for modern construction, designed to ..

Best Places to Buy Bar Bending Machines Near Me – By Topall Impex When it comes to modern con..

In today’s fast-paced construction industry, efficiency, precision, and durability are essenti..

In the modern construction industry, efficiency, precision, and reliability are non-negotiable. One ..

In modern construction, efficiency, precision, and durability are crucial for completing projects on..

In the booming construction industry of India, efficiency, precision, and cost-effectiveness are cru..

In the fast-growing construction sector of India, bar bending machines are indispensable for efficie..

In India’s fast-paced construction industry, time is money. Contractors, builders, and infrast..

In India’s growing construction sector, every project demands precision, efficiency, and relia..

In India’s rapidly growing construction sector, bar bending machines are essential for shaping..

In India’s booming construction industry, bar bending machines are indispensable for efficient..

Bar Cutting Machines: A Comprehensive Guide to Industrial Cutting Solutions Bar Cutting Machines I..

Bar Threading Machine: The Complete Guide to Precision Threading Solutions In modern construction a..