/ Date: 12 Feb, 2026

Bar Threading Machine: The Complete Guide to Precision Threading Solutions

In modern construction and manufacturing, achieving precise, consistent threads on reinforcement bars is critical for structural integrity. A bar threading machine has revolutionized how contractors and manufacturers create threaded connections, replacing labor-intensive manual methods with automated precision. Whether you're working on high-rise buildings, bridges, or industrial projects, understanding bar threading machines can significantly impact your project efficiency and quality.

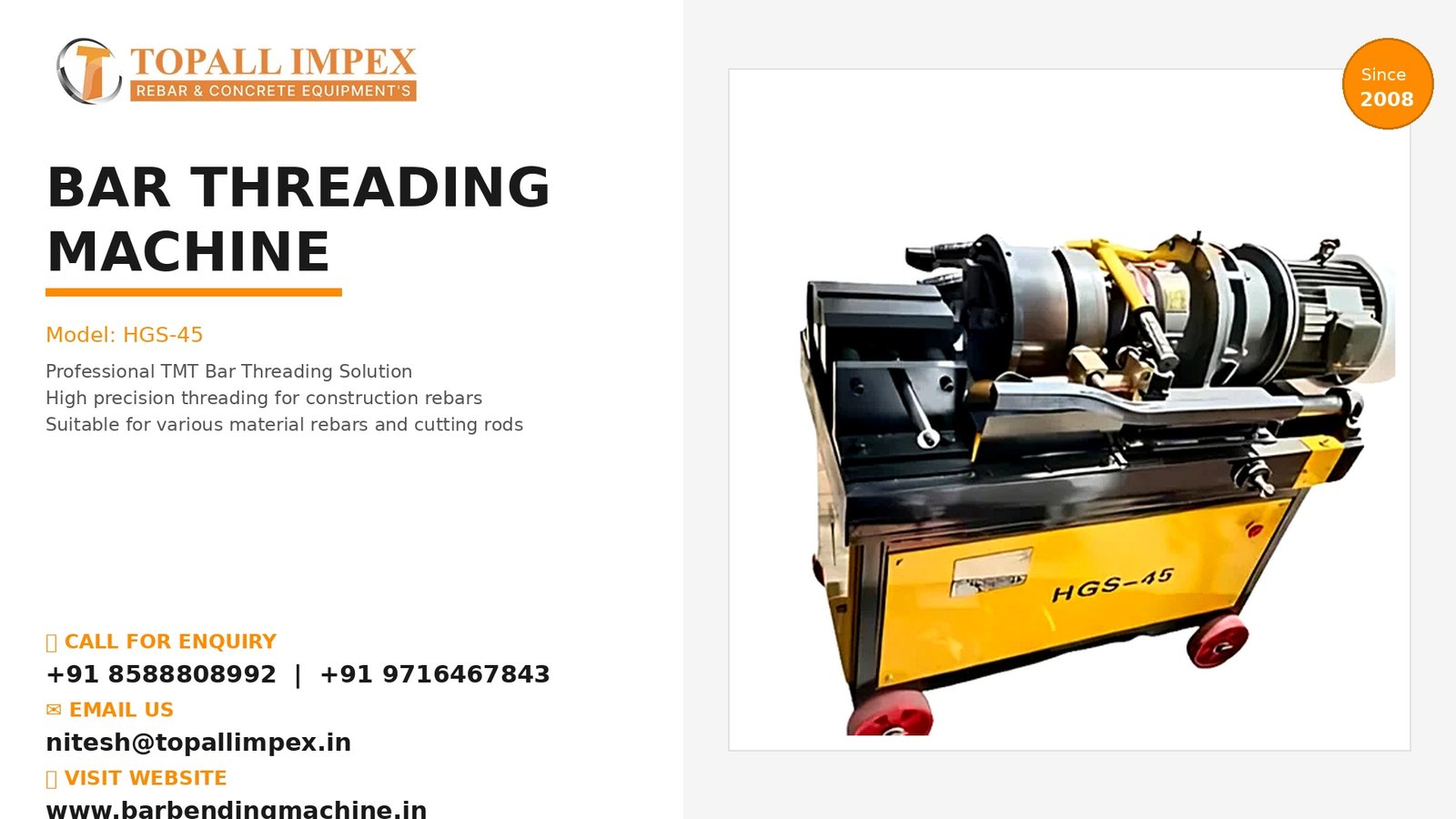

Bar Threading Machine

A bar threading machine is a specialized industrial equipment designed to cut precise helical threads onto reinforcement bars (rebars), steel rods, and metal bars used in construction and manufacturing. This automated machine creates standardized thread profiles on bar ends, enabling mechanical connections through couplers instead of traditional lap splicing or welding methods.

Bar threading machines deliver exceptional productivity gains compared to traditional threading methods. These automated systems can thread multiple bars in the time it takes to manually thread a single piece.

Modern bar threading machine manufacturers have developed models capable of threading bars ranging from 12mm to 40mm diameter in minutes rather than hours. Automated feeding systems eliminate downtime between operations, while hydraulic mechanisms ensure consistent threading speed regardless of bar diameter or steel grade.

Construction teams report productivity increases of 300-500% when switching from manual to machine threading. This speed advantage becomes crucial during large-scale projects where thousands of threaded connections are required. Bar threading machine suppliers often provide production calculators to help you estimate time savings for your specific project requirements.

Thread quality directly impacts the structural integrity of mechanical splicing systems. Bar threading machines produce ISO-standard threads with exceptional consistency and accuracy.

Computer-controlled depth settings ensure every thread meets exact specifications, eliminating human error from the equation. The precision cutting dies create clean, uniform threads that facilitate easier coupling installation and provide superior load transfer capabilities.

Unlike manual threading where fatigue can affect quality, machines maintain the same precision from the first bar to the thousandth. This consistency is particularly valuable for projects requiring certification and quality assurance documentation. Leading steel bar threading machine manufacturers incorporate quality monitoring systems that alert operators to any deviation from specifications.

Modern bar threading machines serve diverse industries beyond traditional construction. Their versatility makes them invaluable across multiple sectors:

Construction Industry: High-rise buildings, bridges, tunnels, and underground structures require thousands of threaded bar connections for reinforcement continuity.

Infrastructure Projects: Road expansions, metro systems, and dam construction utilize threaded bars for segmental construction and seismic-resistant designs.

Industrial Manufacturing: Precast concrete manufacturers use threading machines for producing standardized components with threaded connection points.

Geotechnical Applications: Rock bolts and soil anchors rely on threaded bars for stabilization in mining and slope protection projects.

Most bar threading machine suppliers offer models compatible with various bar grades including TMT bars, HYSD bars, and international standards like ASTM A615. This adaptability ensures you can thread different materials without investing in multiple specialized machines.

While the initial investment in a bar threading machine may seem substantial, the return on investment typically occurs within 6-12 months for active contractors.

Direct Cost Savings: Reduced labor costs, faster project completion, and minimal material wastage contribute to immediate savings. A single operator can manage machine threading, whereas manual methods often require multiple workers.

Reduced Material Waste: Precision cutting minimizes defective threads, reducing material rejection rates to below 1%. Traditional methods can see waste rates exceeding 5-8% due to improper threading.

Long-Term Durability: Quality machines from reputable rebar threading machine manufacturers last 10-15 years with proper maintenance, spreading the investment across hundreds of projects.

Energy Efficiency: Modern electric and hydraulic models consume significantly less energy than older pneumatic systems, reducing operational costs while maintaining performance.

Safety remains paramount when operating industrial machinery. Contemporary bar threading machines incorporate multiple protective features:

Emergency Stop Systems: Easily accessible emergency shut-off buttons halt operations instantly during anomalies.

Protective Guards: Enclosures shield operators from flying debris and rotating components during the threading process.

Automatic Clamping: Secure bar-holding mechanisms prevent slippage and kickback, which are common hazards in manual threading.

Overload Protection: Built-in sensors detect excessive force and automatically stop operations, preventing machine damage and operator injury.

Reputable bar threading machine suppliers provide comprehensive operator training, ensuring teams understand safety protocols and proper operation procedures. This training significantly reduces workplace accidents and improves overall site safety records.

Understanding the differences between machine and traditional threading helps justify the investment:

Manual Threading:

Bar Threading Machines:

The productivity gap becomes even more significant on large projects. What might take a manual crew weeks to complete, a bar threading machine accomplishes in days, accelerating project timelines and reducing labor costs.

Proper maintenance ensures optimal performance and extends machine lifespan. Follow these essential maintenance practices:

Daily Maintenance:

Weekly Maintenance:

Monthly Maintenance:

Annual Maintenance:

Maintaining a detailed service log helps track machine performance and identify patterns that might indicate developing issues. Many bar threading machine suppliers offer maintenance contracts providing regular servicing and priority access to replacement parts.

Selecting the appropriate machine requires evaluating several critical factors:

Production Volume: Assess your threading requirements. Small contractors might need portable models handling 20-30 bars daily, while large manufacturers require industrial machines processing hundreds of bars per shift.

Bar Size Range: Ensure the machine accommodates your typical bar diameters. Universal machines handle 12mm-40mm ranges, while specialized models focus on specific diameter categories.

Power Source: Electric models suit locations with stable power supply, hydraulic systems offer higher torque for larger bars, and diesel-powered portable units work for remote sites.

Portability Requirements: Stationary machines provide maximum stability for shop environments, while portable models mounted on wheels or trailers suit contractors moving between job sites.

Budget Considerations: Balance initial investment against features, capacity, and expected lifespan. Premium machines from established bar threading machine manufacturers cost more initially but offer superior reliability and support.

After-Sales Support: Evaluate warranty coverage, spare parts availability, and technical support responsiveness. Local bar threading machine suppliers with established service networks provide faster issue resolution.

Automation Level: Basic manual-feed machines cost less and suit smaller operations, while fully automated models with programmable controls maximize efficiency for high-volume production.

Topall Impex has established itself as a trusted name in construction equipment supply, offering comprehensive solutions for threading requirements.

Extensive Product Range: Topall Impex partners with leading bar threading machine manufacturers worldwide, providing access to the latest technology and proven models across all capacity ranges.

Quality Assurance: Every machine undergoes rigorous testing before delivery, ensuring it meets international standards and performs reliably from day one.

Competitive Pricing: Direct manufacturer relationships and efficient operations allow Topall Impex to offer competitive pricing without compromising quality or service.

Technical Expertise: Their experienced team provides expert consultation, helping you select the right machine configuration for your specific requirements and budget.

Comprehensive Support: From installation and operator training to ongoing maintenance support and spare parts supply, Topall Impex delivers complete lifecycle support for your equipment investment.

Pan-India Service Network: Strategically located service centers ensure prompt support regardless of your project location, minimizing downtime and maintaining productivity.

Customization Options: Working closely with manufacturers, Topall Impex can arrange customized configurations to meet unique project specifications or special threading requirements.

Investing in a quality bar threading machine represents a strategic decision that impacts project efficiency, quality, and profitability. The combination of enhanced productivity, superior thread precision, improved safety, and long-term cost savings makes machine threading the clear choice for modern construction and manufacturing operations.

As construction methodologies evolve toward mechanical splicing and prefabrication, threaded bar connections have become industry standard rather than specialty applications. Organizations that adopt bar threading technology position themselves competitively for future projects while improving current operations.

Working with experienced bar threading machine suppliers like Topall Impex ensures you receive not just equipment, but comprehensive solutions including proper machine selection, installation support, operator training, and ongoing technical assistance. This partnership approach maximizes your investment return and ensures successful implementation.

Whether you're a contractor looking to improve productivity, a manufacturer seeking consistent quality, or a project manager evaluating threading solutions, understanding bar threading machine capabilities empowers informed decisions that drive project success. The technology continues advancing with smarter controls, enhanced automation, and improved efficiency, making now an excellent time to upgrade your threading capabilities.

Choose the right bar threading machine, implement proper maintenance practices, and partner with reliable suppliers to transform your threading operations and achieve superior project outcomes.

Looking for the perfect bar threading machine for your projects? Contact Topall Impex today for expert consultation and discover how advanced threading solutions can elevate your construction capabilities.

Trusted by leading brands and businesses across industries

Nowadays, the bar cutting machine has become one of the essential tools on the construction site, as..

Amongst the very vital tools both in construction and landscaping activities are plate compactors. W..

Machines used in polishing concrete find very wide application in modern construction and interior: ..

There are a range of construction machines but the most underrated among them is the Rebar Processin..

There is a variety of uses in the use of advanced equipment, ranging from concrete mixers to pumps a..

Toyo machines have ranked high as far as quality and efficient machinery is concerned in the constru..

Speed, accuracy and life span are the keys to success in the construction and infrastructure industr..

In construction business, the factors present in successful business entails safety, speed, and savi..

In the construction industry contractors are ever faced with pressure to deliver quality ..

Introduction The construction business has experienced an enormous change over the recent decades. ..

Introduction In the world of modern construction, time, precision, and safety play a crucial role i..

Throughout the construction sector, accuracy and productivity are not only welcome attributes but al..

Construction is an industry in which precision, stability, and performance determine the standards o..

In the current fast developing field of construction, efficiency and accuracy is the key to success...

In the modern construction industry, speed, accuracy, and efficiency are critical factors that deter..

Introduction Construction work demands precision, stability, and durability at every stage. Before ..

Introduction Construction technology has advanced rapidly, especially in the high-rise building sec..

Introduction In today’s competitive construction industry, efficiency and accuracy are non-ne..

Introduction Construction industry is among the most significant industries in the worldwide develo..

Introduction In the construction industry, steel reinforcement plays a vital role in ensuring the s..

Introduction – The Importance of Surface Preparation The construction and flooring industries..

Introduction In today’s fast-paced construction industry, efficiency, accuracy, and safety ar..

Concrete finishing is one of the most critical stages in any construction project. Achieving smooth,..

Modern construction demands tools that combine precision, efficiency, and safety. One essential piec..

Introduction India’s construction industry is experiencing unprecedented growth. With rapid u..

Introduction Modern construction projects demand efficiency, precision, and safety. One of the most..

Introduction In modern construction, the quality of road surfaces depends heavily on proper compact..

Construction projects today require a combination of efficiency, precision, and safety. The introduc..

Introduction: Rising Demand in Construction India’s construction sector is advancing at a rem..

Introduction: Advancing Construction with Modern Machinery Bar bending machines are transforming In..

A Bar Bending Machine is a crucial tool in construction, helping workers bend steel rebars effi..

Introduction In modern construction, efficiency, safety, and precision are essential. Among the wid..

Introduction The Rebar Threading Machine is an essential tool for modern construction, designed to ..

Best Places to Buy Bar Bending Machines Near Me – By Topall Impex When it comes to modern con..

In today’s fast-paced construction industry, efficiency, precision, and durability are essenti..

In the modern construction industry, efficiency, precision, and reliability are non-negotiable. One ..

In modern construction, efficiency, precision, and durability are crucial for completing projects on..

In the booming construction industry of India, efficiency, precision, and cost-effectiveness are cru..

In the fast-growing construction sector of India, bar bending machines are indispensable for efficie..

In India’s fast-paced construction industry, time is money. Contractors, builders, and infrast..

In India’s growing construction sector, every project demands precision, efficiency, and relia..

In India’s rapidly growing construction sector, bar bending machines are essential for shaping..

In India’s booming construction industry, bar bending machines are indispensable for efficient..

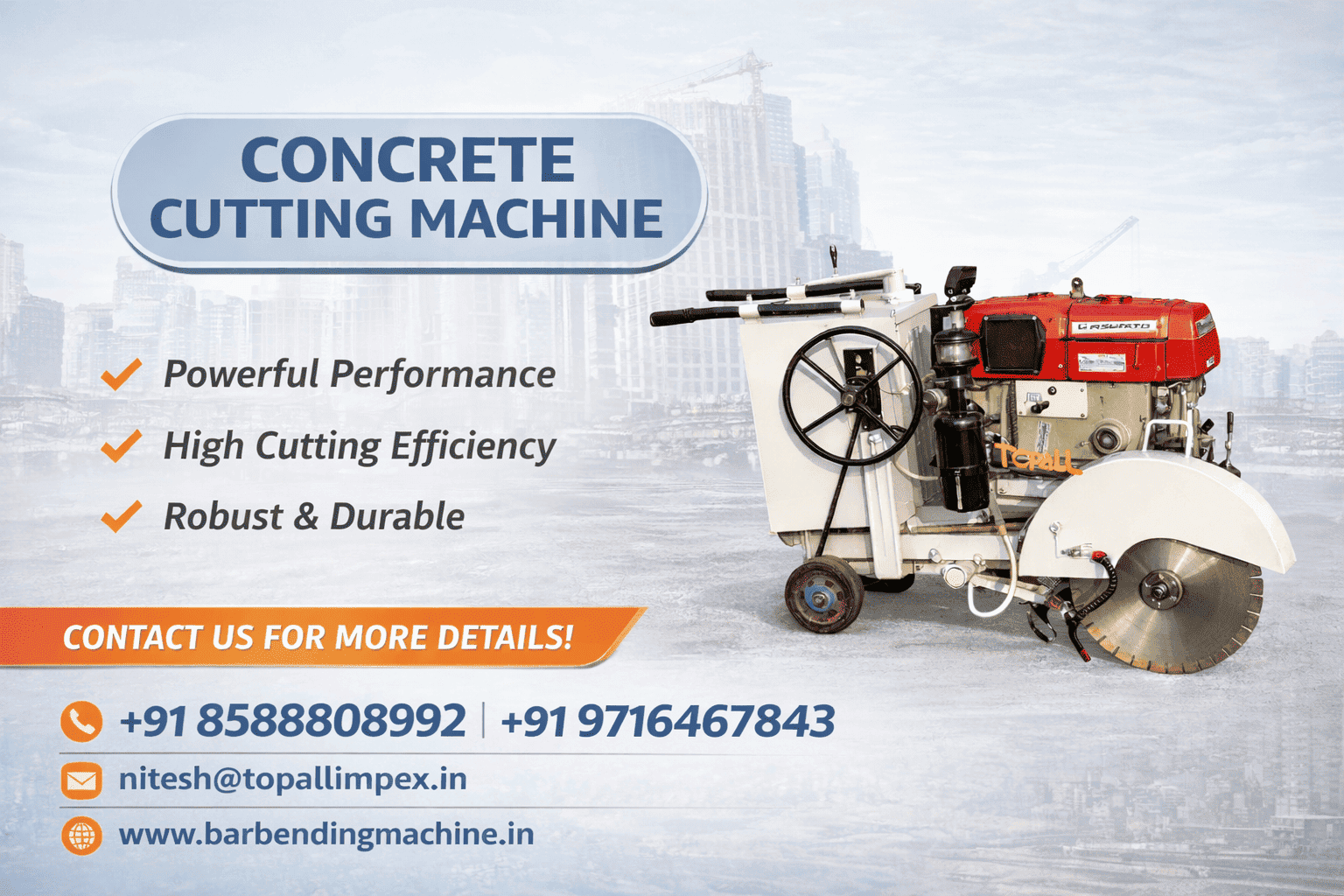

When precision meets power in construction, concrete cutting machines become indispensable. Whether ..

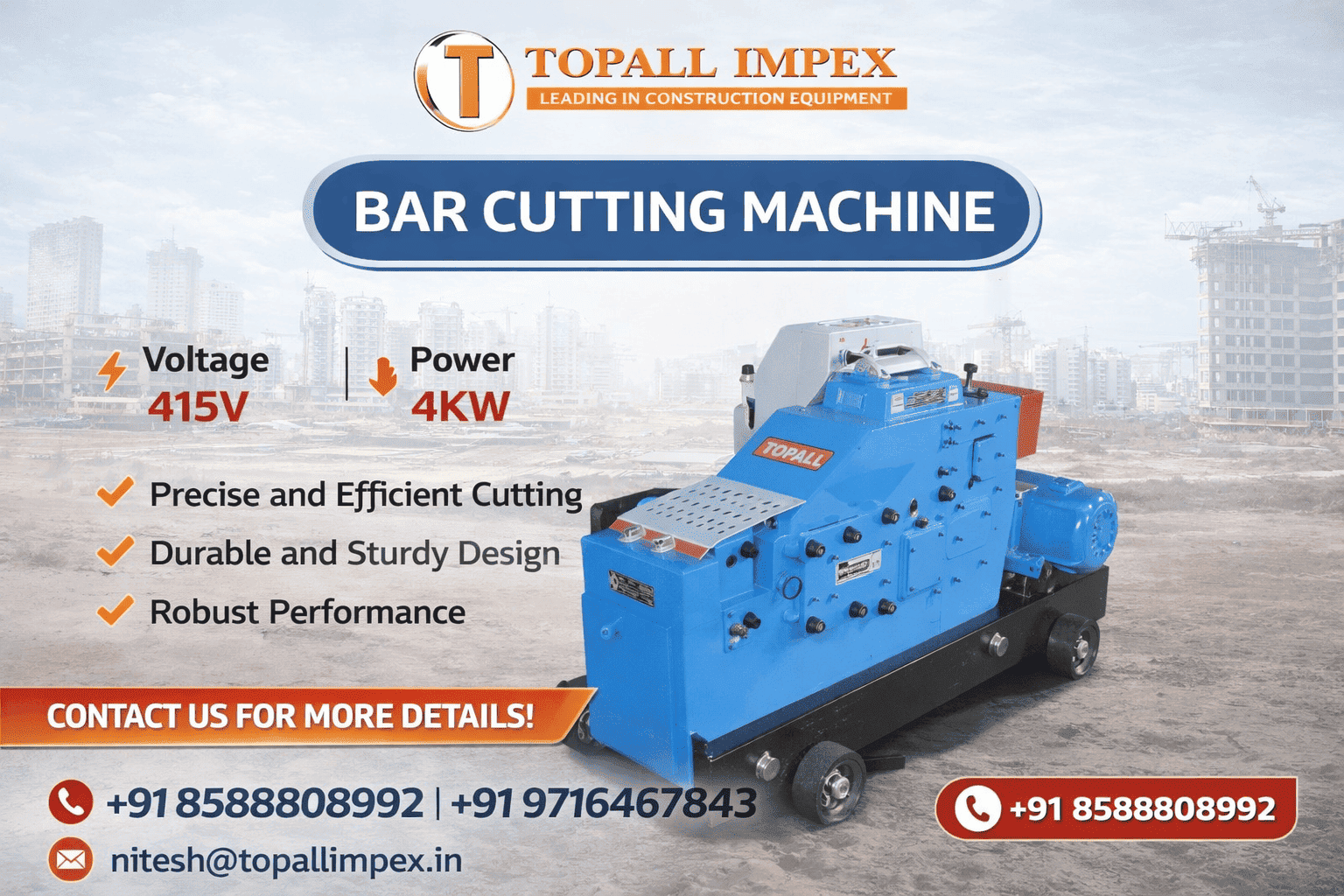

Bar Cutting Machines: A Comprehensive Guide to Industrial Cutting Solutions Bar Cutting Machines I..