Introduction

In Bawana, modern construction projects demand precise and efficient reinforcement processing. A Bar Bending Machine automates the bending of rebars, ensuring accuracy and reducing labor. For growing infrastructure and commercial projects in Bawana, adopting advanced bending solutions is critical.

To explore technological trends in bending tools, see More about Bar Bending Machine innovations here:

Bar Bending Machine Innovations – Driving India’s Modern Construction Growth

What Exactly Does a Bar Bending Machine Do?

A bar bending machine in Bawana is a mechanical device engineered to bend reinforcement bars (rebars) into required angles and curves per structural designs. It replaces labor-intensive manual bending with fast, precise, and repeatable operations.

Core Functions

-

Bending rebars to exact angles

-

Handling multiple bar diameters

-

Ensuring uniform bend radii

-

Reducing human error

Modern machines combine robust mechanics, electric motors, and control systems to achieve consistent output across multiple cycles.

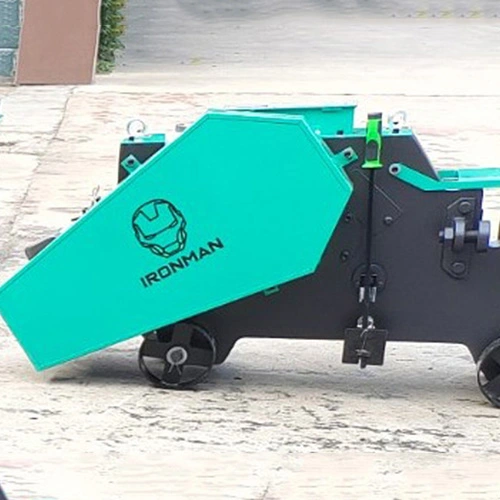

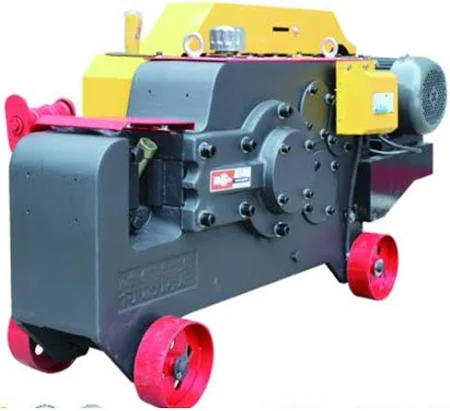

Types of Bar Bending Machines

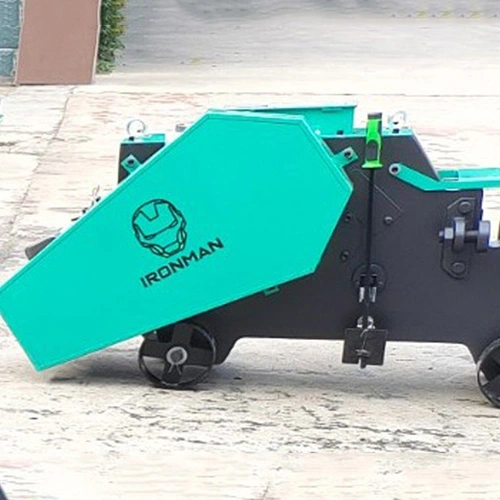

Manual Bar Bending Machines

Operated by hand or simple mechanical aids. Suitable for small-scale or on-site jobs in Bawana with limited budgets.

Semi-Automatic Bar Bending Machines

Combine manual input with motorized support. Operator positions the bar and triggers the machine.

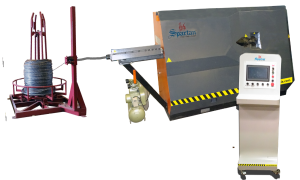

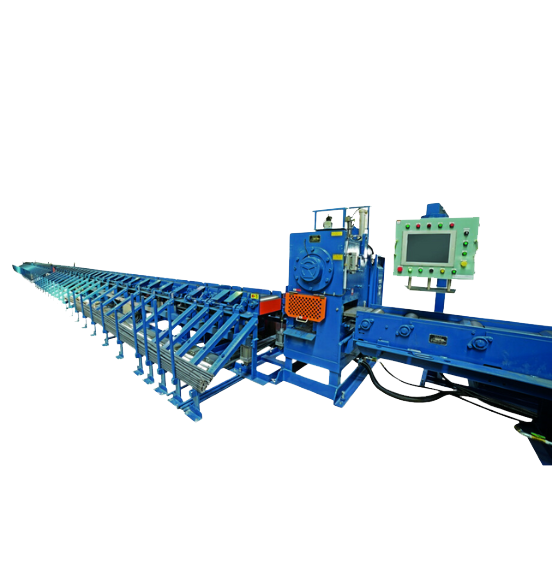

Automatic / Fully Automatic Bar Bending Machines

Accept digital input parameters and bend bars automatically. Ideal for medium to large construction jobs in Bawana.

CNC Bar Bending Machines

Equipped with programmable logic controllers (PLCs) or computer numerical control. Suitable for complex projects like bridges, precast factories, or metro constructions in Bawana.

Technical Specifications to Consider

When choosing a bar bending machine in Bawana, check:

-

Bar Diameter Capacity: 6 mm – 40 mm; heavy-duty up to 50–55 mm

-

Bending Angle Range: 0° up to 180° or 360°

-

Motor Power: 3 HP to 7.5 HP

-

Bending Speed / Cycle Time: 5–10 seconds per bend

-

Machine Weight: 300 kg – 600 kg

-

Voltage & Power Supply: Typically three-phase (e.g., 415V, 50 Hz)

-

Control Method: Mechanical, digital panel, or CNC

Working Principle & Operation

-

Bar Loading: Insert the rebar into the bending slot or clamp.

-

Angle Setting: Adjust via stops or digital input.

-

Bending Motion: Motor rotates disc or roller, bending the bar.

-

Bar Unloading: Bent bar is removed for placement.

Advanced machines in Bawana may perform multiple bends automatically.

Applications Across Construction Projects in Bawana

-

Residential & Commercial Buildings: Columns, beams, slabs

-

Infrastructure Projects: Bridges, flyovers, tunnels

-

Industrial Complexes: Factories, warehouses, plants

-

Precast Concrete Factories: Mass-bent elements

-

Public Projects: Metro stations, airports, dams

Advantages of Using Bar Bending Machines in Bawana

-

Speed & Productivity

-

Accuracy

-

Reduced Labor Costs

-

Material Efficiency

-

Safety

-

Longevity

For detailed guidance on maintenance, see:

Maintenance Tips for Bar Bending Machines – Ensure Longevity & Efficiency

Choosing the Right Machine in Bawana

Project Scale & Output

-

Small: manual/semi-automatic

-

Medium/Large: automatic/CNC

Rebar Diameter

Ensure machine covers largest required bar size.

Control Mode

Manual vs digital/CNC for precision.

Build Quality & Support

Strong frame, gearbox, safety, and after-sales service.

Maintenance Best Practices in Bawana

-

Lubricate moving parts

-

Clean after each use

-

Inspect bending plates and pins

-

Check wiring and motor connections

-

Schedule full servicing

-

Store in dry, sheltered environment

Challenges & Considerations

-

Initial cost

-

Stable power supply

-

Operator training

-

Parts availability

Future Trends in Bar Bending Technology

-

Robotics & automation

-

Smart IoT-enabled monitoring

-

Energy efficiency

-

BIM/CAD integration

-

Adaptive bending feedback systems

Frequently Asked Questions (FAQs)

Q1: Maximum bar size? → Standard 40 mm; heavy-duty 50–55 mm

Q2: Can multiple bars be bent simultaneously? → Yes, for small diameters

Q3: Operation complexity? → Basic simple; advanced need training

Q4: Expected lifespan? → 7–10+ years

Q5: Is CNC worth the cost? → Yes, for high-volume and complex jobs

Conclusion

Bar bending machines in Bawana streamline reinforcement processing with speed, accuracy, and durability. Suitable for small to large projects, they reduce labor, increase efficiency, and ensure structural precision.

For more tools enhancing construction efficiency in Bawana, check out:

Light Construction Equipment