Machinery Portal

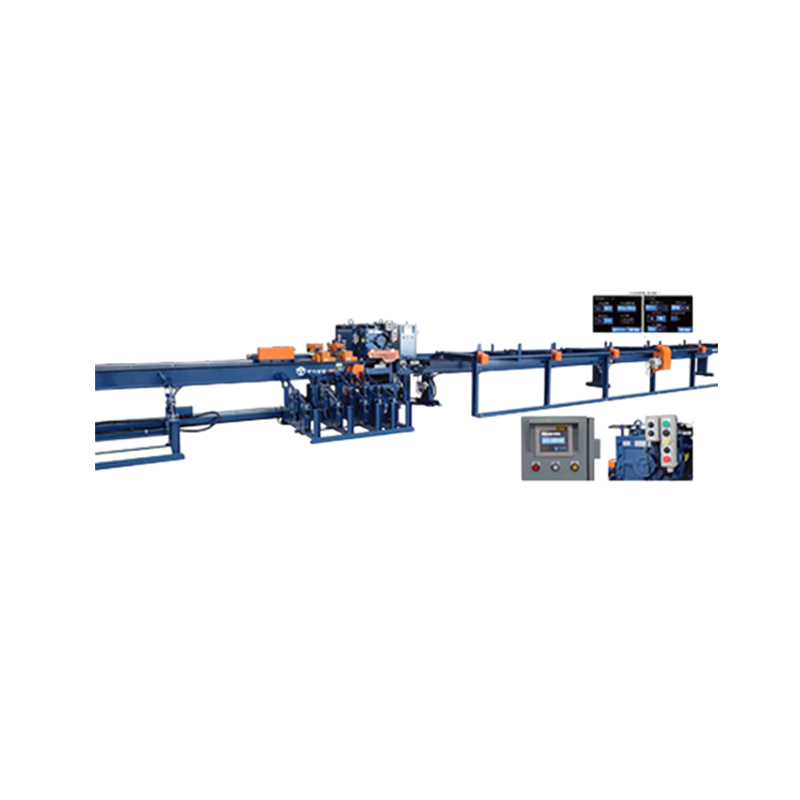

Automatic Bender Line

Technical Intelligence

Usage/Application

Automatic Bender Line

Max Bending Radius

0-50 mm

Model Name/Number

GW20

Power Source

Electric

Voltage

415 V

Weight In Kg

90 - 95

Bending Range

4 - 16 mm

Model

GW 20

Minimum order quantity

1 Unit

Country of Origin

Made in India

Technical Variants

| Usage/Application | Automatic Shear Line |

| Max Bending Radius | 0-50 mm |

| Model Name/Number | GW20 |

| Power Source | Electric |

| Voltage | 415 V |

| Weight In Kg | 90 - 95 |

| Bending Range | 4 - 16 mm |

| Model | GW 20 |

| Minimum order quantity | 1 Unit |

| Country of Origin | Made in India |

| Usage/Application | Automatic Stirrup Machine |

| Max Bending Radius | 0-50 mm |

| Model Name/Number | GW20 |

| Capacity | 10mm |

| Bar Dimensions | 32 mm (TMT Bar) |

| Brand | Topall |

| Max Bending Angle | 180 Degree |

| Max Bending Radius | 21 mm |

| Frequency | 50 Hz |

| Country of Origin | Made in India |

| Usage/Application | Mesh Bender |

| Automation Grade | Semi-Automatic |

| Model Name/Number | GW-42J |

| Power Source | Electric |

| Bar Dimensions | 32 mm (TMT Bar) |

| Brand | Topall |

| Max Bending Angle | 180 Degree |

| Max Bending Radius | 21 mm |

| Frequency | 50 Hz |

| Country of Origin | Made in India |